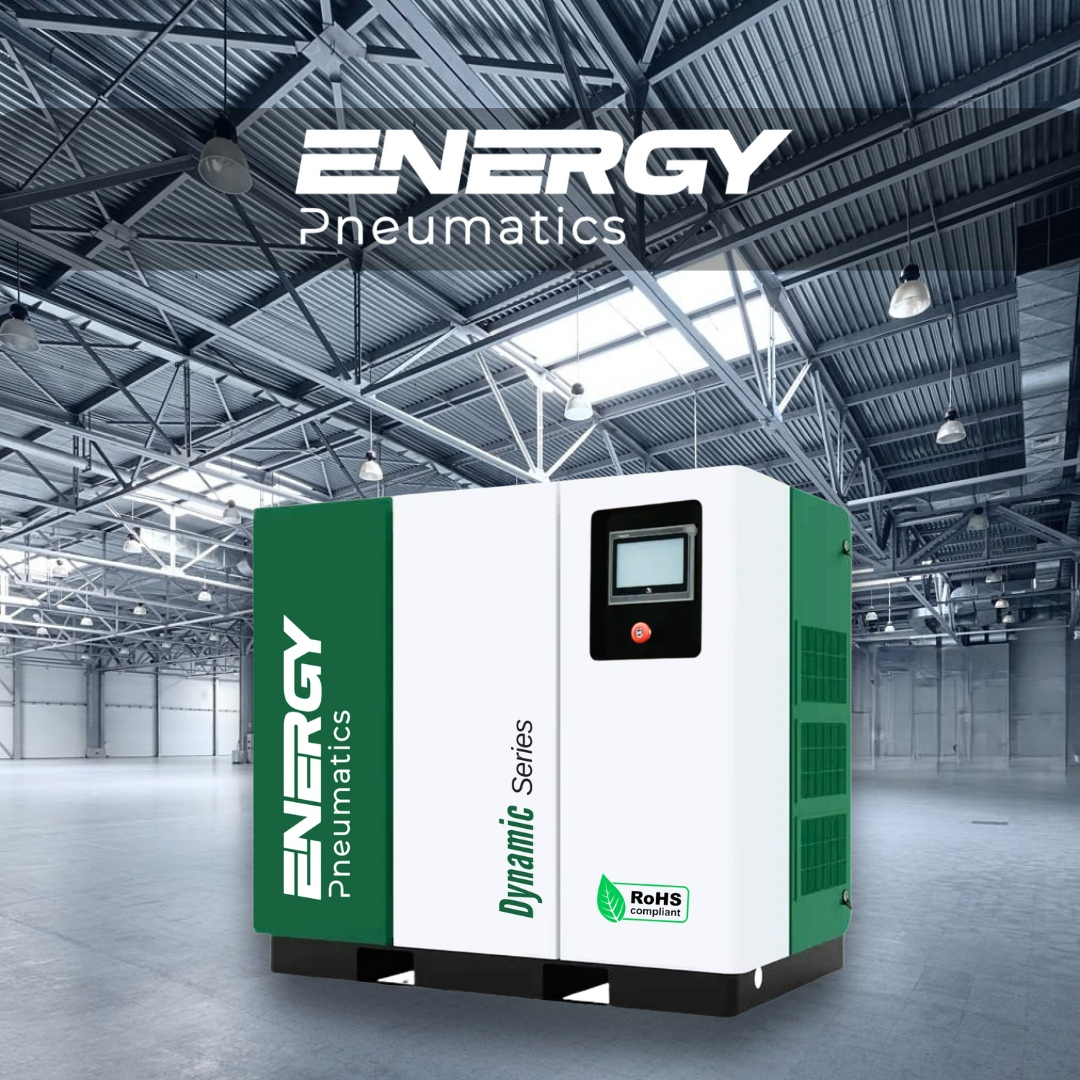

Best Rotary Screw Air Compressor Manufacturers in India. In today's demanding industrial landscape, efficiency, durability, and consistent performance are essential. One machine that plays a crucial role in achieving these goals is the Rotary Screw Air Compressor. When it comes to quality compressors, Energy Pneumatics is proud to be recognized as one of the Top Rotary Screw Air Compressor Manufacturers & Suppliers in Gujarat. This blog will walk you through the technical highlights of our compressors, their applications, and how you, as a customer, benefit from choosing Energy Pneumatics. Understanding Rotary Screw Air Compressors Unlike traditional piston compressors, rotary screw air compressors use two interlocking helical screws to compress air. This method ensures: • Continuous, pulsation-free airflow • High energy efficiency • Reduced maintenance costs • Quieter operation • Long-term reliability These qualities make them the preferred choice across various industries, from manufacturing to food processing. Technical Specifications : At Energy Pneumatics, our Dynamic Series Rotary Screw Air Compressors are designed to deliver maximum performance with optimal energy efficiency. The key specifications include: • Model Name: Dynamic Series • Nominal Power: 3.7 kW to 150 kW • Working Pressure: 7 to 10 bar • Free Air Delivery: 0.5 to 25.50 cubic meters per minute • Electric Motor Type: Induction Motor • Drive Options: Available in both belt-driven and direct-driven models • Cooling System: Air-cooled • Optional Features: Variable Speed Drive (VSD) for enhanced control and efficiency • Control Panel: User-friendly PLC interface for easy operation • Noise Level: Engineered for low-noise operation, adhering to industry standards These specifications are meticulously crafted to suit industries of all scales, ensuring consistent air supply and efficiency. Applications: serve a wide range of applications. Their reliability and adaptability make them suitable for: Manufacturing Sector: Perfect for powering assembly lines, automation systems, CNC machines, and other production equipment requiring a stable air supply. Automotive Industry: Ideal for operating air tools, painting booths, tire inflation, and other workshop operations demanding continuous airflow. Food and Beverage Industry: Ensures clean, contaminant-free air essential for packaging, bottling, and food processing environments adhering to strict hygiene standards. Pharmaceutical Industry: Used in processes like mixing, drying, and maintaining sterile clean-room conditions where consistent, oil-free air is necessary. Textile and Printing: Supports weaving, dyeing, printing, and other processes, helping maintain smooth production without interruptions. Customer Benefits: Choosing Energy Pneumatics means more than just purchasing a product; it’s an investment in quality, efficiency, and long-term reliability. Here’s how customers benefit: Unmatched Reliability: Our compressors are engineered for durability, ensuring minimal downtime and smooth, continuous operation. Energy Efficiency: Built with advanced technology, our compressors reduce power consumption, resulting in substantial cost savings on electricity bills. Low Maintenance: With fewer moving parts and optimized designs, maintenance needs are significantly lower compared to conventional systems. Noise Reduction: Our compressors are specifically designed to operate quietly, creating a safer, more comfortable working environment. Customization Options: We understand that every business has unique needs. That’s why we offer flexible customization options, including variable speed drives and tailored configurations. Expert Assistance and After-Sales Support: From product selection to installation and ongoing support, our expert team ensures you receive the guidance and assistance you need at every step. Call Us For More Information.

Chat with us on WhatsApp

×

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

https://www.screwaircompressor.in/latest-update/best-rotary-screw-air-compressor-manufacturers-in/29

Best Rotary Screw Air Compressor Manufacturers in ...

2025-03-18T07:21:24

Best Rotary Screw Air Compressor Manufacturers in India. In today's demanding industrial landscape, efficiency, durability, and consistent performance are essential. One machine that plays a crucial role in achieving these goals is the Rotary Screw Air Compressor. When it comes to quality compressors, Energy Pneumatics is proud to be recognized as one of the Top Rotary Screw Air Compressor Manufacturers & Suppliers in Gujarat. This blog will walk you through the technical highlights of our compressors, their applications, and how you, as a customer, benefit from choosing Energy Pneumatics. Understanding Rotary Screw Air Compressors Unlike traditional piston compressors, rotary screw air compressors use two interlocking helical screws to compress air. This method ensures: • Continuous, pulsation-free airflow • High energy efficiency • Reduced maintenance costs • Quieter operation • Long-term reliability These qualities make them the preferred choice across various industries, from manufacturing to food processing. Technical Specifications : At Energy Pneumatics, our Dynamic Series Rotary Screw Air Compressors are designed to deliver maximum performance with optimal energy efficiency. The key specifications include: • Model Name: Dynamic Series • Nominal Power: 3.7 kW to 150 kW • Working Pressure: 7 to 10 bar • Free Air Delivery: 0.5 to 25.50 cubic meters per minute • Electric Motor Type: Induction Motor • Drive Options: Available in both belt-driven and direct-driven models • Cooling System: Air-cooled • Optional Features: Variable Speed Drive (VSD) for enhanced control and efficiency • Control Panel: User-friendly PLC interface for easy operation • Noise Level: Engineered for low-noise operation, adhering to industry standards These specifications are meticulously crafted to suit industries of all scales, ensuring consistent air supply and efficiency. Applications: serve a wide range of applications. Their reliability and adaptability make them suitable for: Manufacturing Sector: Perfect for powering assembly lines, automation systems, CNC machines, and other production equipment requiring a stable air supply. Automotive Industry: Ideal for operating air tools, painting booths, tire inflation, and other workshop operations demanding continuous airflow. Food and Beverage Industry: Ensures clean, contaminant-free air essential for packaging, bottling, and food processing environments adhering to strict hygiene standards. Pharmaceutical Industry: Used in processes like mixing, drying, and maintaining sterile clean-room conditions where consistent, oil-free air is necessary. Textile and Printing: Supports weaving, dyeing, printing, and other processes, helping maintain smooth production without interruptions. Customer Benefits: Choosing Energy Pneumatics means more than just purchasing a product; it’s an investment in quality, efficiency, and long-term reliability. Here’s how customers benefit: Unmatched Reliability: Our compressors are engineered for durability, ensuring minimal downtime and smooth, continuous operation. Energy Efficiency: Built with advanced technology, our compressors reduce power consumption, resulting in substantial cost savings on electricity bills. Low Maintenance: With fewer moving parts and optimized designs, maintenance needs are significantly lower compared to conventional systems. Noise Reduction: Our compressors are specifically designed to operate quietly, creating a safer, more comfortable working environment. Customization Options: We understand that every business has unique needs. That’s why we offer flexible customization options, including variable speed drives and tailored configurations. Expert Assistance and After-Sales Support: From product selection to installation and ongoing support, our expert team ensures you receive the guidance and assistance you need at every step. Call Us For More Information.

2025-03-18T07:21:24

Keywords

- 5 Hp Screw Air Compressor

- 10 Hp Screw Compressor With Dryer

- 60 Hp Rotary Screw Air Compressor

- Screw Air Compressor Manufacturers

- Rotary Screw Air Compressor With Dryer

- 50 Hp Air Compressor

- Screw Drive Air Compressor

- Rotary Compressor

- Rotary Air Compressor in India

- Rotary Screw Compressor

- Screw Air Compressor Suppliers in India

- Screw Air Compressor in Ahmedabad

- Screw Compressor

- Rotary Screw Air Compressors Dealers in Gujarat

- Rotary Screw Air Compressors Suppliers in India

- Rotary Screw Air Compressors in Ahmedabad

- Rotary Screw Air Compressors in Gujarat

- Rotary Screw Air Compressors in India

- Rotary Screw Air Compressors

- interlocking helical screws

- lownoise operation adhering

- production equipment requiring

- substantial cost savings

- fewer moving parts

- optimized designs maintenance

- significantly lower compared

- operate quietly creating

- variable speed drives

- expert team ensures

- deliver maximum performance

- optimal energy efficiency

- manufacturing sector perfect

- consistent oilfree air

- longterm reliability heres

- efficiency applications serve

- consistent performance

- quality efficiency

- compress air

- energy pneumatics

- crucial role

- technical highlights

- customer benefit

- qualities make

- preferred choice

- 2550 cubic meters

- enhanced control

- industry standards

- meticulously crafted

- wide range

- adaptability make

- packaging bottling

- mixing drying

- advanced technology

- aftersales support

- ongoing support

- step call

- key specifications

- suit industries

- specifically designed

- product selection

Submit Your Enquiry